Mechanical & Manual Bar Screen

Bar screens are mechanical screening devices used to remove large solids such as sticks, rags, plastics, and other debris from wastewater in water treatment plants. They are typically installed at the beginning of the treatment process to protect downstream equipment from damage and blockages. Bar screens consist of vertical or inclined bars spaced at regular intervals to allow water to pass through while capturing solid materials. These screens can be manually or automatically cleaned to ensure continuous operation. Bar screen are essential in maintaining the efficiency and effectiveness of wastewater treatment processes, helping to prevent clogging and reducing maintenance costs.

Bar Screens are designed for the continuous operation to provide free racking of the vertical screen grid by means of parallel raking beams continuously. Micro raked bar screens remove suspended and floating coarse debris such as weed, reed, rags etc., from surface water. These screens are mainly used in:

- Pumping stations

- Sewage treatment plants

- Cooling water inlets

The various types of bar screens are of robust design and made of suitable steels. Vertical screens are arranged across the channel and dead plate fix area is between the top of the bars and it is the discharge point of the debris.

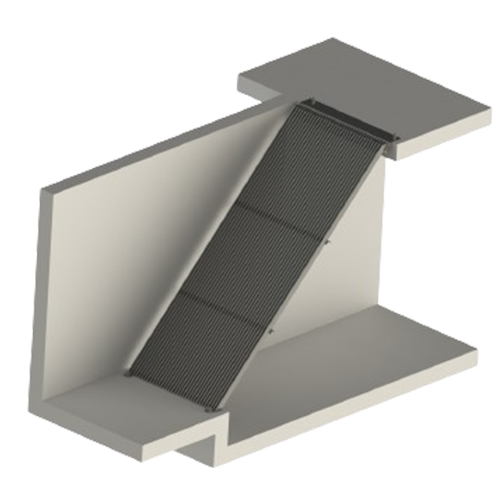

Manual Bar Screen

Manual bar screen with vertical flat bars spaced apart is used to prevent large and medium floating debris from travelling further into the screening chamber. These are generally installed at the upstream of Mechanical bar screen as well as a standby to the mechanical bar screen. Cleaning of screen is done manually with the help of manual rake comb provided with the screen. Manual screen can be provided either as fixed type or removable type.

A manual bar screen is a simple but effective wastewater treatment equipment used to remove large solids such as debris, plastics, and other materials from water or wastewater streams. It consists of vertical or inclined steel bars spaced evenly to form a grid or screen. The screen is manually cleaned by operators using rakes or other tools to remove the accumulated debris. Manual bar screen are commonly used in municipal wastewater treatment plants, industrial facilities, and storm water management systems to protect pumps, pipes, and other downstream equipment from clogging and damage. Regular maintenance and cleaning of manual bar screens are essential to ensure efficient operation and prevent costly downtime

| Clear gap | 6 mm and above. |

|---|---|

| Channel width | Maximum up to 3,000 mm. |

| Channel depth | Maximum up to 5,000 mm. |

| Mode of operation | Manual |

| Material of Contruction | Carbon Steel / Stainless Steel 304, 316 / Duplex / Super Duplex. Other Material on request. |

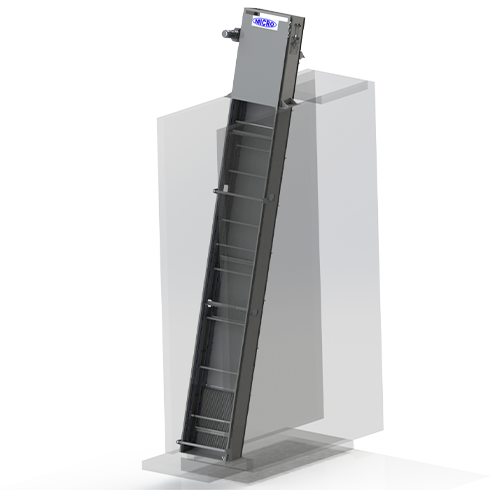

Multirake Bar Screen

| Bar Spacing | 8 mm & above |

|---|---|

| Channel width | 500 mm |

| Channel depth | Maximum up to 12,000 mm. |

| Mode of operation | Motorized |

| Material of Contruction | SS 304 & SS 316 |

Step Screen (Fine Screen)

| Bar Spacing | 2 mm to 3 mm |

|---|---|

| Channel width | 500 mm to 1600 mm. smaller width on request |

| Channel depth | 1850 mm |

| Mode of operation | Hydraulic |

| Material of Contruction | SS 304 & SS 316 |

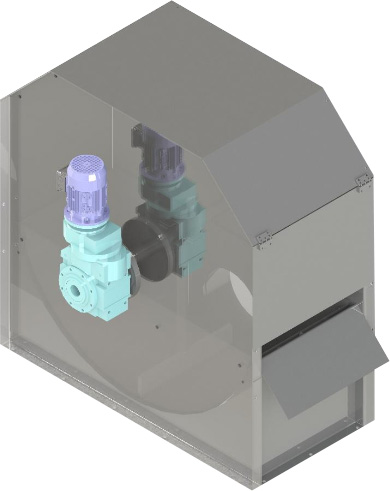

Half Drum Rotary Screen

Key Features:

- Ideal for pre-screening MBR feed to safeguard membranes from abrasion or damage caused by solid particles.

- Features a perforated, semi-circular screening element.

- Equipped with multiple rotating cleaning brushes made of nylon or polypropylene.

- Constructed from carbon steel with a powder-coated finish or stainless steel (304/316).

- Available with hole sizes of 1 mm, 2 mm, 3 mm, and 5 mm.

- Specifically designed for MBR applications.

- Includes a piped inlet for efficient flow management.

- Designed for continuous, uninterrupted operation

| MODEL | FLOW RATE IN CUM/Hr (m3 /hr) AS PER HOLE DIAMETER |

POWER | INLET SIZE | |||

| 1 mm | 2 mm | 3 mm | 5 mm | HP | NB | |

| MHDS 800 -400 | 30 | 40 | 60 | 80 | 0.25 | 150 |

| MHDS 800 -700 | 45 | 60 | 90 | 120 | 0.25 | 200 |

| MHDS 1200-500 | 60 | 80 | 120 | 160 | 0.5 | 250 |

| MHDS 1200 – 1000 | 115 | 150 | 220 | 300 | 0.5 | 300 |

| MHDS 1600 -1000 | 160 | 210 | 310 | 420 | 0.5 | 400 |

| MHDS 1600 – 2000 | 320 | 420 | 620 | 840 | 0.5 | 500 |

Screw Screen

Basket Screens

This screen can be installed in a Manhole prior to pumps, the size depending on the inflow rate and depth. The sturdy, stable basket screen retains the floating debris at the sewer outlet. The screen bottom plate is perforated to allow static dewatering of the retained material. When a certain amount of material has accumulated, the screen basket is lifted upwards by an electric hoist. The vertical basket movement is supported by a stable carrier and guide rails. These rails are curved in the upper section to ensure a partly automatic discharge into a suitable container. While the screenings are transported upwards in the basket, material which could impair the function of downstream pumps is removed by a fall screen supported on guide rollers. Control of the screen can be either manual or electrical.