Sludge Dryer

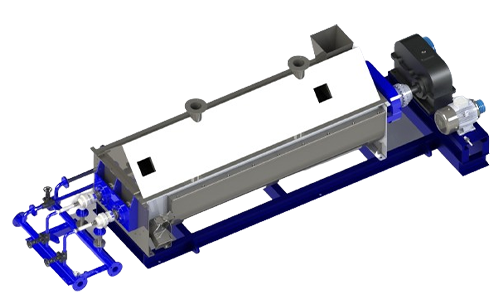

Hollow Paddle Sludge Dryer

Micro Sludge dryer has been designed and developed for drying of different types of sludge paste like biological & chemical sludge. These machines are highly efficient, mechanically agitated, indirect heating by steam or thermic fluid. There are two counter rotating paddle shaft with uniquely designed intermeshing wedge type paddles that produce intimate mixing and self-cleaning of heat transfer surface for optimization of heat transfer resulting in minimizing the footprint of machine.

Electric Heating Sludge Dryer

Micro Batch type Sludge Dryer is designed with electric heating system upto 300 kg per 3hr/batch.

Solar Sludge Dryer

Micro Transmission Systems is a reputed manufacturer of water and wastewater treatment solutions. The firm was founded in 1995 to serve engineering industry and later on we moved to serve water/ waste water treatment industry as per growing need of society and worldwide scarcity.

SSDR – I: SYSTEM SPECIFICATION

- A rain protected hall with horizontal surface, Either asphalt or Concrete.

- Electrical power supply

- Access of Road to both side of hall (sludge entry and dried sludge exit)

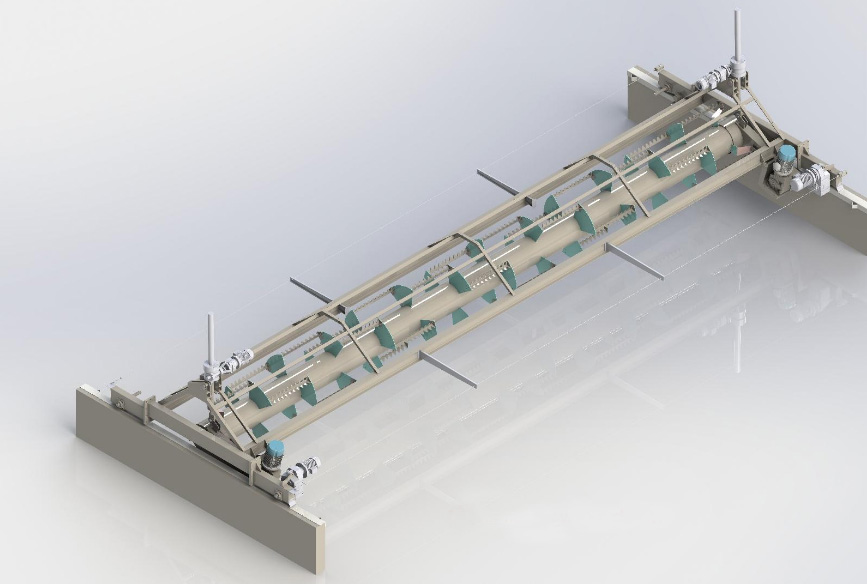

- A Micro make Sludge turner machine that is equipped with sensors and control unit. The turner drum is equipped with comb type scrapper which aerates the sludge bed and pushes sludge to exit side.

- Operating Control Panel

- Safety switch on both sides of the Turner.

- Greenhouse covered with polycarbonate sheet.

- Circulation fan is fitted below roof and exhaust fans at both ends of green house.

- Cable and cable trolley for the bus bar system of the machine

- Instrumental Equipment (for installation inside on each hall and outside the halls)

- Tilling and conveying machine for sewage sludge MTS TURNER.

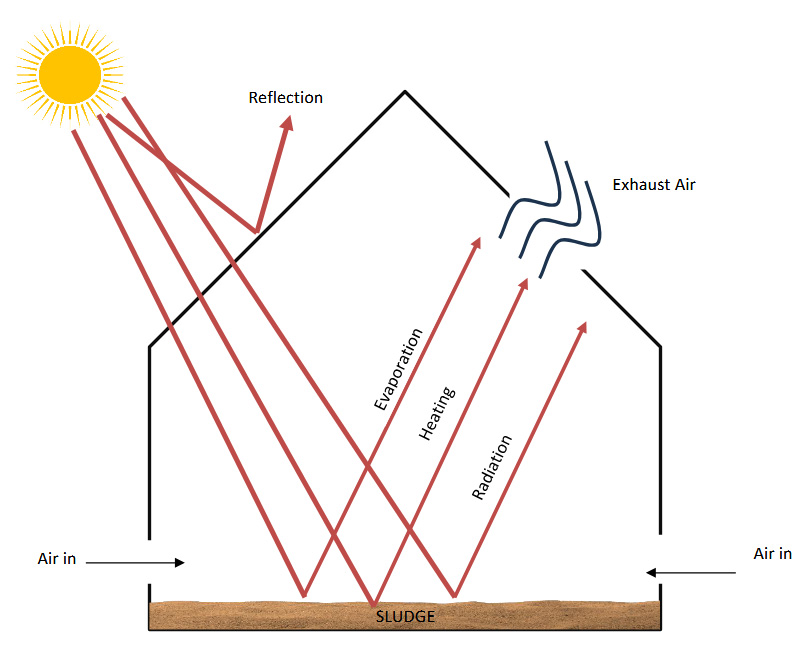

SSDR – II: HOW IT HAPPENS

Sewage treatment plants generate sludge as excess biomass during the biological treatment of wastewater. This biomass, typically wasted during the treatment process, initially contains less than 1% solids. It is first mechanically dewatered to achieve a solids content of 18–20%. The dewatered sludge is then transported to a greenhouse structure covered with specially coated polycarbonate sheets. These sheets are designed to optimize solar energy utilization, allowing direct solar radiation to effectively dry the wet sludge. When automatic conveyor systems are unavailable, sludge is delivered by truck or tractor trolley and unloaded onto the greenhouse floor at a maximum height of 60 cm. A sludge turner then agitates and spreads the material across the floor, maintaining a uniform layer approximately 50 mm thick. Solar heat causes water in the sludge to evaporate, drying the top layer while lower layers remain moist, necessitating periodic turning. Evaporation increases humidity within the greenhouse. Ceiling-mounted circulation fans, installed at 10 m intervals, direct heated air downward toward the sludge surface. This airflow removes the moisture-laden layer formed by evaporation, redistributing it into the greenhouse interior. Exhaust fans located at both the inlet and outlet ends of the greenhouse expel the saturated air, simultaneously drawing in fresh air to maintain optimal drying conditions Fresh sludge is loaded at the entry side of the greenhouse daily. The sludge turner pushes the material incrementally toward the exit end. Due to its higher rotational speed compared to its forward movement, the turner simultaneously aerates the sludge, enhancing the drying process. Once the sludge achieves the desired dryness, it is removed from the system using a loader. The process operates continuously, with new sludge being introduced and dried sludge being removed each day. All system operations, including fan control and turner movement, are remotely monitored and managed to ensure consistent performance and efficiency.

Advantages of Micro Solar Drying Technology:

- Operates solely on solar energy, eliminating reliance on external power sources.

- Dramatically lowers sludge disposal costs compared to conventional drying methods.

- Consumes significantly less electricity than alternative drying technologies.

- Reduces sludge volume by up to 75%, minimizing handling and transportation demands.

- Produces stable, granulated sludge suitable for long-term, odor-free storage.

- Completes a full pass along the 120 m hall in just 48 minutes, effectively preventing fermentation.

- Utilizes a precision-engineered comb-type spreader/mixer to inhibit fermentation and eliminate foul odors.

- Transforms sludge into a dry, easily handled granular form for efficient transport and management.

- Eliminates the need for back-mixing of wet and dry sludge, enhancing drying efficiency and avoiding operational complications.

- Ensures gradual, continuous drying along the hall, achieving optimal dryness at the outlet without intermediate processing.

- Fitted with a safety rope switch to immediately halt operation and prevent accidents involving operators or external objects.