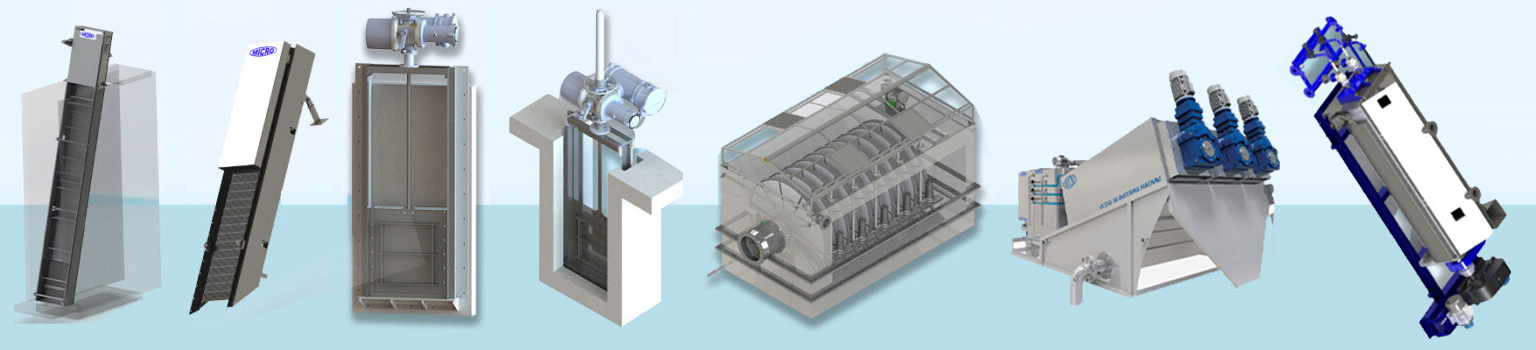

Sludge Dewatering Machine

The ‘Micro’ Sludge Dewatering Machine is unique in construction and offers de-watering at a very low energy consumption with very high solid yield in dewatered sludge. The machine operates at a very low sound level with negligible vibration. It is the industry’s dream machine that is easy to operate and simple to maintain.

The Machine has a unique concept of thickening and pressing in single cylinder. That’s why ‘Micro’ Sludge Dewatering Machine can work at a very low concentration of slurry. With this feature, it can operate without any thickener. It can take slurry directly from the treatment process such as sludge sump/clarifiers/oxidation ditches and can give dewatered sludge up to 20% of solids.

1. Expertise: With a team of skilled engineers and technicians, Micro Transmission Systems has the expertise to design and manufacture high-quality sludge dewatering machines that meet the specific requirements of our customers.

2. Quality: We use only the best materials and components to ensure that our machines are durable, reliable, and efficient. Our commitment to quality is reflected in the performance of our machines.

3. Customization: At Micro Transmission Systems, we understand that every customer has unique needs. That’s why we offer customized solutions to meet the specific requirements of our clients. Whether you need a machine for a small-scale operation or a large industrial facility, we can tailor our products to suit your needs.

4. Service: Our team is dedicated to providing excellent customer service. From initial consultation to installation and maintenance, we are committed to ensuring that our customers are satisfied with their purchase.

The Process of Sludge Dewatering

Sludge dewatering is a crucial process in the treatment of wastewater. It involves removing water from sludge to reduce its volume and make it easier to handle and dispose of Sludge dewatering machines play a key role in this process, utilizing various techniques such as gravity dewatering, mechanical dewatering, and thermal drying to achieve optimal results.

Sludge dewatering Machine is a crucial step in wastewater treatment processes to reduce the volume of sludge for disposal. Several methods are commonly used for sludge dewatering, including:

- Belt Filter Press: A device that uses a series of rollers to squeeze water out of the sludge.

- Centrifugation: Involves spinning the sludge at high speeds to separate the water from the solids.

- Filter Press: Utilizes pressure to force water out of the sludge through a series of filter plates.

- Drying Beds: Allows the sludge to dry out naturally through evaporation.

- Dewatering Bags: Sludge is placed in bags, and the water drains out through the fabric.

Geotextile Tubes: Similar to dewatering bags but on a larger scale.

At Micro Transmission Systems, we offer a range of sludge dewatering machines to suit different applications and requirements. Our machines are designed to deliver high performance, energy efficiency, and cost-effectiveness, making them the ideal choice for industries such as wastewater treatment plants, food processing facilities, and municipal sewage systems.

| Model | Flow Rate m 3/hr (Low concentration Sludge 10gm/lt (1%)) | Dry Sludge Through Input Kgs./Hr | Cylinder Specification | Electrical Power (HP) | Dimensions (mm) | Rinsing Water Consumption (LPH) | Static Weight (Kgs) | Dynamic Weight (Kgs)s | ||

| L | W | H | ||||||||

| MTS 1075 | 0.5 | 5 | 80 X 1 | 0.18 | 1750 | 700 | 1100 | 20 | 190 | 240 |

| MTS 1110 | 1.5 | 15 | 110 X 1 | 0.5 | 2100 | 850 | 1100 | 30 | 230 | 310 |

| MTS 2110 | 3 | 30 | 110 X 2 | 0.75 | 2100 | 950 | 1100 | 60 | 310 | 400 |

| MTS 1160 | 4 | 40 | 150 X 1 | 0.75 | 2400 | 900 | 1300 | 40 | 300 | 390 |

| MTS 1210 | 5 | 50 | 210 X 1 | 0.75 | 3159 | 1000 | 1500 | 40 | 550 | 680 |

| MTS 1250 | 8 | 80 | 250 X 1 | 1 | 3400 | 1000 | 1700 | 100 | 600 | 800 |

| MTS 2210 | 10 | 100 | 210 X 2 | 1.25 | 3150 | 1200 | 1500 | 80 | 850 | 1150 |

| MTS 1300 | 14 | 140 | 300 X 1 | 1 | 3800 | 1200 | 1800 | 100 | 800 | 1100 |

| MTS 2250 | 18 | 180 | 250 X 2 | 1.75 | 3500 | 1300 | 1700 | 200 | 900 | 1200 |

| MTS 1350 | 20 | 200 | 350 X 1 | 2.5 | 4300 | 1200 | 2200 | 100 | 1400 | 1800 |

| MTS 2300 | 30 | 300 | 300 X 2 | 2.5 | 4000 | 1350 | 18000 | 200 | 1450 | 1850 |

| MTS 2350 | 45 | 450 | 350 X 2 | 4.5 | 4430 | 1500 | 2300 | 200 | 2300 | 4000 |

| MTS 3350 | 65 | 650 | 350 X 3 | 6.5 | 4700 | 3000 | 2300 | 300 | 3200 | 5000 |

| MTS 1450 | 35 | 450 | 450 X 1 | 2.5 | 4860 | 1330 | 2420 | 120 | 1400 | 2650 |

| MTS 2450 | 70 | 700 | 450 X 2 | 3 | 5300 | 1700 | 2600 | 240 | 3800 | 6600 |

| MTS 3450 | 100 | 1000 | 450 X 3 | 7 | 5800 | 2300 | 2600 | 360 | 5300 | 9900 |