SBR Wastewater treatment is one of the major demands of today, due to intensive urbanization, industrialization and global lack of clean water. The Sequencing Batch Reactor (SBR) is one of the most effective and efficient modern treatment methods. Thanks to SBR Decanter, wastewater treatment plants can reach outstanding standards in water quality, energy consumption and ease of operation.

At Micro Transmission Systems, we produce high performance SBR wastewater treatment decanters that are a perfect blend of traditional trustworthiness and modern innovation to deliver superior wastewater treatment without blowing the budget.

What is SBR in Wastewater Treatment?

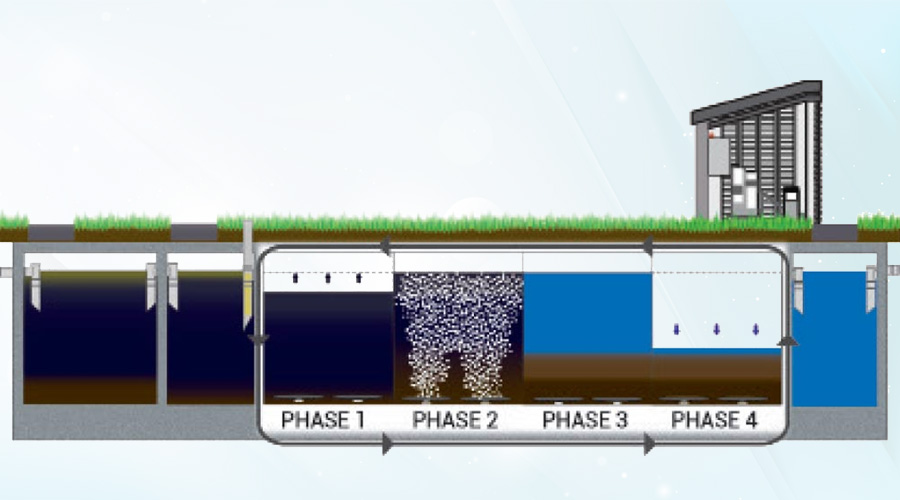

SBR is the acronym for Sequence Batch Reactor, an activated sludge sewage treatment process in which treatment occurs through a sequence of steps carried out sequentially within a single tank. Micro Transmission System design and develop plants with this technology both completely standard and personalized upon customer’s requirements.

The method consists of a filling, aeration, settling and decantation in successive stages all within the same tank. This small and adjustable design also eliminates primary and secondary clarifiers, drastically reducing the plant’s overall footprint.

Why Choose SBR Decanters?

High-Quality Treated Water

The SBR Decanter produces treated wastewater that is recyclable and meets recyclable effluent standards having very low BOD, COD and TSS. This renders the water fit for direct industrial reuse and other non-potable purposes. Substances such as ammonia (NH4) and nitrogen total (TN), phosphorus TP are reduced to extremely low values allowing an easy compliance with the strict environmental regulations.

Versatility in Load Variations

SBR Decanters are well-suited to taking fluctuations in flows and wastewater qualities into account. They are automatically regulating water levels and oxygen input during real-time circumstances, which maintain constant treatment operation and minimize operating costs.

Energy Efficiency

It can significantly reduce power consumption by taking control of oxygen supply automatically. The introduction of Variable Frequency Drives (VFDs) allows blowers to speed up or slow down as demand calls for it, reducing even more electricity when compared to traditional methods.

Compact Design and Space Saving

A major benefit of SBR systems is the decrease in footprint. With a 50% smaller footprint only, due to the absence of multiple clarifiers, this system is great for plants with limited space.

Automation for Hassle-Free Operation

Micro Transmission System’s SBR wastewater treatment decanters are controlled by sophisticated PLC software and data acquisition system to give you a fully automated centrifuge. Operators can simply view performance, review historical data or allow the system to manage critical processes such as sludge removal, aeration cycles and decanting rate. This minimizes human work and reduces the operation cost greatly.

Final Thoughts

SBR Decanters are the next generation of wastewater treatment–small footprint, unmanned and efficient with a sustainable function. They are capable of producing high quality treated water while minimizing operating costs and aiding in the preservation of the environment.

If you want high performance SBR wastewater treatment machinery, Micro Transmission Systems has the best in class for your needs.