Vortex Grit Separator

HOW IT WORKS

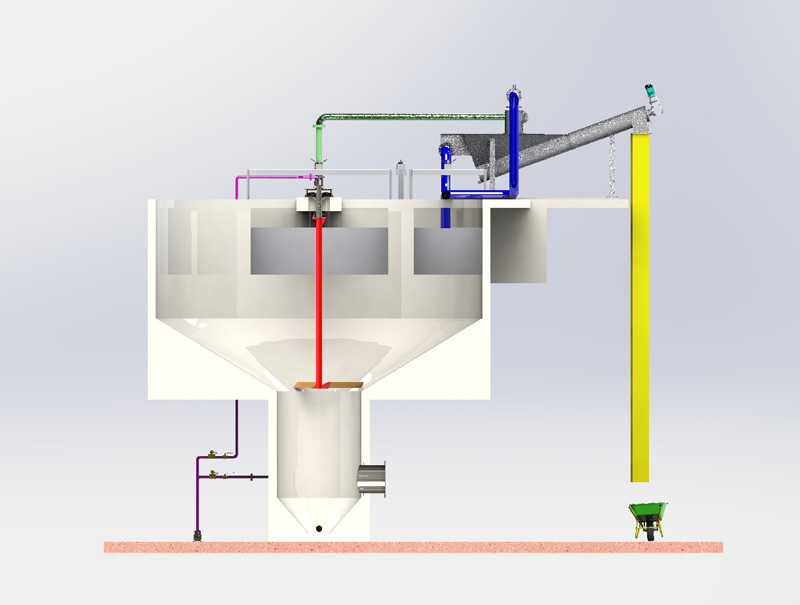

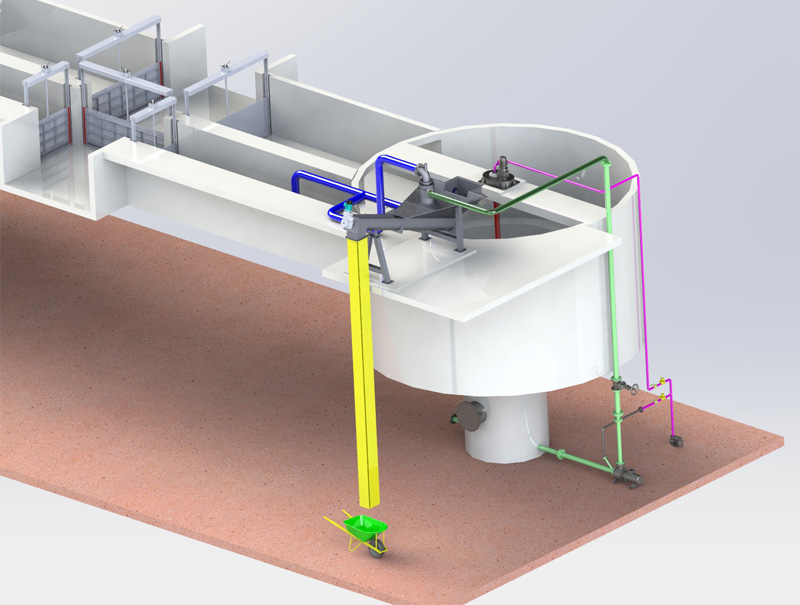

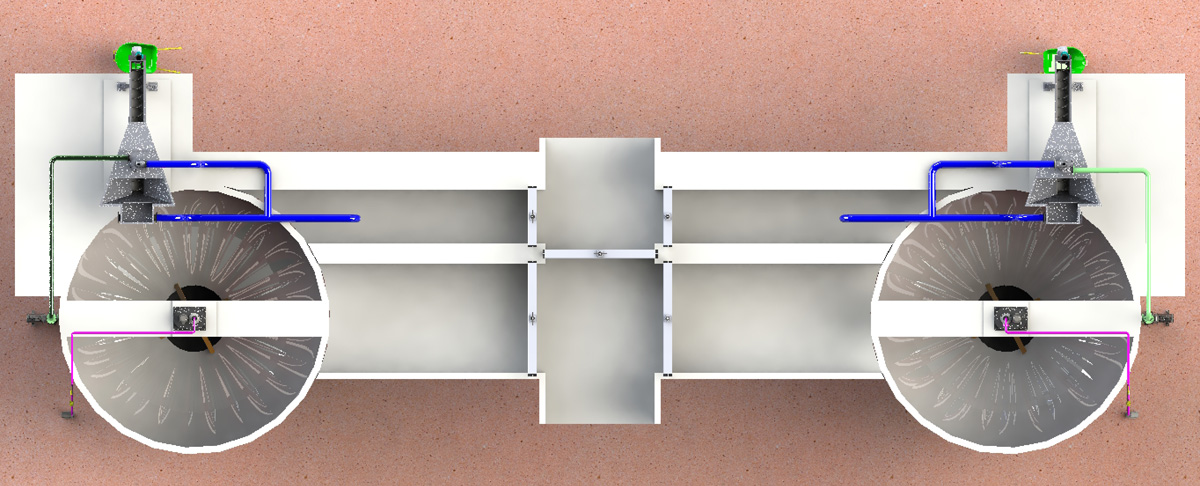

The grit trap is a compact, circular system positioned within the main flow of the inlet stream. Effluent enters tangentially, creating a rotational flow within the tank, and exits in alignment with the inlet. This design ensures effective settling of grit in the lower hopper, which is then transferred to a separate plant for washing, classification, and dewatering. With its angled walls and specially designed impeller, the system efficiently separates heavy mineral solids (grit) while preventing larger and lighter particles from settling, keeping them suspended in the water flow. By removing abrasive solids, the grit trap protects downstream equipment from wear, ensuring improved performance and reduced maintenance. Functional Zones for Efficient Separation The system operates with two distinct zones:- Outer Zone (Calm): Promotes settling of grit and fine solids onto the sloped chamber floor.

- Inner Zone (Spiral Motion): Controlled by the impeller’s rotational speed, this zone generates radial forces to direct grit into the collection hopper while keeping lighter particles suspended. These lighter solids are carried upward and discharged with the water flow.

- The circular tank is typically constructed from concrete, with the bridge cast on-site

- The impeller mechanism, located on the bridge, can be either belt-driven or gear-driven as per diagram.

- Grit pump is connected to control sump for transfer of grits to Hydro Cyclone to classifer.

- Automatic system for fluidising of settled grit and cleaning of pump discharge line.

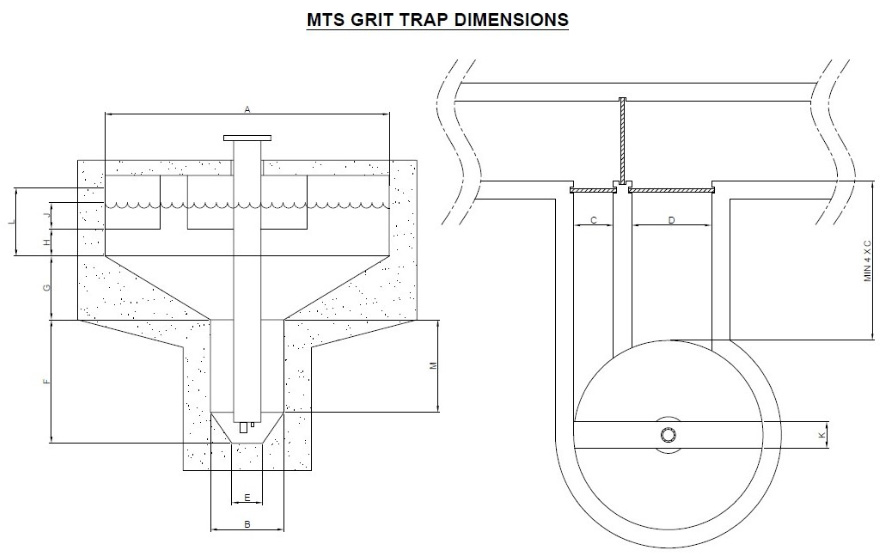

MTS GRIT TRAP DIMENSIONS in MM

| MTS Model | Flow (MLD) | A | B | C | D | E | F | G | H | I | J | K | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VGS-4 | 4 | 1850 | 1020 | 330 | 640 | 310 | 1400 | 310 | 310 | 210 | 810 | 1090 | 1050 |

| VGS-10 | 10 | 2170 | 1020 | 410 | 790 | 310 | 1400 | 310 | 310 | 310 | 810 | 1090 | 1050 |

| VGS-15 | 15 | 2440 | 1020 | 460 | 915 | 310 | 1400 | 410 | 310 | 410 | 810 | 1120 | 1050 |

| VGS-30 | 30 | 3100 | 1020 | 460 | 1260 | 310 | 1500 | 460 | 310 | 460 | 810 | 1350 | 1125 |

| VGS-50 | 50 | 3720 | 1500 | 795 | 1585 | 410 | 1700 | 610 | 510 | 590 | 810 | 1450 | 1275 |

| VGS-75 | 75 | 4880 | 1500 | 1000 | 1990 | 410 | 2210 | 1000 | 510 | 610 | 810 | 1860 | 1658 |

| VGS-100 | 100 | 5460 | 1500 | 1040 | 2100 | 410 | 2210 | 1000 | 610 | 640 | 810 | 1860 | 1658 |

| VGS-150 | 150 | 5800 | 1500 | 1220 | 2440 | 410 | 2520 | 1300 | 760 | 690 | 810 | 1960 | 1890 |

| VGS-200 | 200 | 6170 | 1500 | 1400 | 2850 | 410 | 2520 | 1300 | 760 | 760 | 810 | 1960 | 1890 |

| VGS-260 | 260 | 7320 | 1500 | 1680 | 3350 | 410 | 2520 | 1300 | 760 | 1680 | 810 | 2850 | 1890 |

| VGS-375 | 375 | 8540 | 1500 | 1980 | 3960 | 410 | 3000 | 1525 | 760 | 1980 | 810 | 3200 | 2250 |

| VGS-425 | 425 | 9150 | 1500 | 2140 | 4270 | 410 | 3050 | 1625 | 760 | 2140 | 810 | 3430 | 2288 |

KEY FEATURES

- Superior grit separation efficiency

- Streamlined, space-efficient design

- Fully automated system ensuring minimal head loss

- Built-in grit washing functionality for optimal performance

- Adaptable for installation both above and below ground

- Eliminates the need for submerged maintenance access

- Rejects low-density grit and organic contaminants with precision