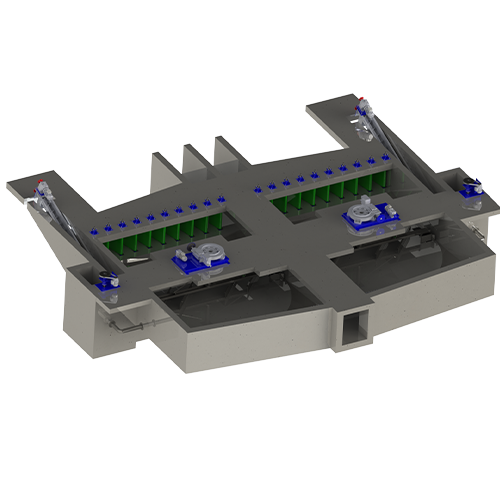

The grit removal consists of two essential elements- grit collecting mechanism and grit washing mechanism. Each operates separately but in hydraulic communication with each other.

The detritor is a continuous flow tank in which the grit settles due to gravity and the water overflows through the outlet weir on the opposite side. The settled grit is scrapped by means of a scraper mechanism towards the openings on the classifier sidewall at the bottom.

The collection chamber works on velocity principle and is so designed that only grit settles down and organic matter overflows. The classifier mechanism consists of a reciprocating rake/screw driven by a gear drive fitted with a motor. The grit collected is given a thorough washing and is delivered from the top of the classifier through a chute for further disposal. The Organic Return Pump / Mixer returns the washed organic liquor lying in the classifier back to the Detritor collection chamber.

| Application | Generally used in sewage treatment plants/ effluent treatment plants, to remove the grit particles sizing greater than 0.15mm having density of 2.65. |

|---|---|

| Type | Conventional type centrally driven bridge mounted |

| Size range | Centrally driven – 1.5m to 16m |

| Rotor | Single stage reduction worm wheel type drive head |

| Torque range | 3400NM – 17000NM |

| Material of construction offered | Mild Steel – E250 & E350 Stainless Steel grades -304, 304L, 316 & 316L Special materials- Super Duplex SS & Marine Grade Aluminium Special coating – hot dip galvanizing |

| Accessories | Rake / screw classifier & organic return mechanism |

| Product Catalogue | |

| GA Drawing |