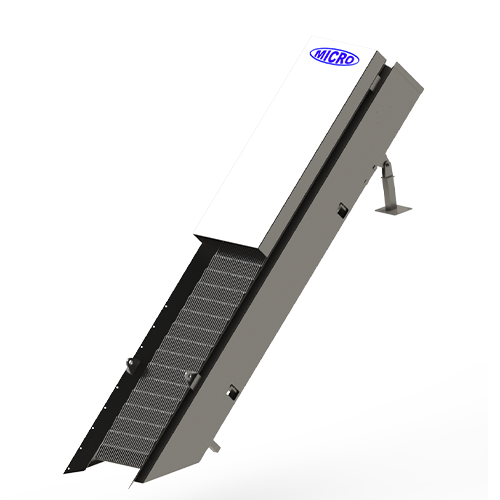

Micro step screen is hydraulically operated Step screen provided with 2 & 3 mm thick equally spaced inclined lamellas to prevent fine sized floating debris from travelling further in to the water and waste water treatment plants. The lamella assembly comprises of a fix set of lamellas and a movable set of lamellas installed at an angle of 40 degree and provided with inverse steps to promote mat formation. The movable lamellas lift the mat of waste deposited over the screen width and deposit them a step above on the set of fixed lamellas. After depositing the mat of debris on to the fixed lamellas, the movable lamellas go back to its lower home position to start a new operation cycle. This way the mat of debris keeps moving upwards in steps till it reaches the discharge point & further to a discharge bin / conveyor. This is a self-cleaning type of screen and does not require any external rake arrangement for lifting the debris deposited on screen.

| Bar Spacing | 02 mm to 01 mm Larger spacing on request |

|---|---|

| Channel width | 500 mm to 1600 mm. smaller width on request |

| Channel depth | up to 17000 mm. |

| Mode of operation | Hydraulic |

| Material of Contruction | Stainless Steel 304, 316 / Duplex / Super Duplex. Other grades of stainless steel on request. |

| Product Catalogue | |

| GA Drawing |

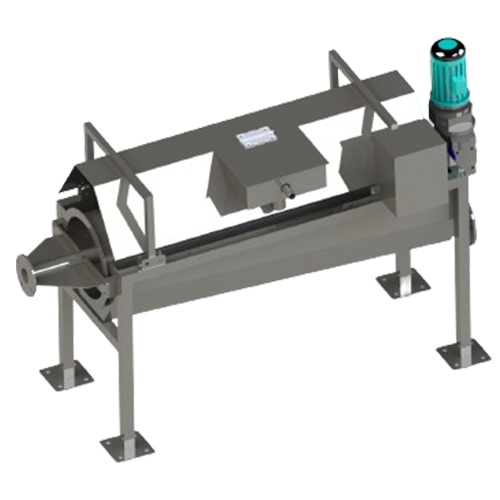

These screens are being used for screening of very small size solid waste like food waste, feather / meat trimmings, fibres, hair etc. The complete screens are made of stainless steel and non corrosive materials for long service life. The filtering screen is made of wedge wire screen that ensures very fine filtration (up to 0.2 mm). High quality of mesh cleaning is ensured by mounting of non-metallic scrapper on drum surface.

These screens are intended for medium and small waste solids from effluent channel and recommended to be used in wastewater treatment plants. It is suitable for effluent channel width from 200 mm – 600 mm and depth up to 4 metres. The perforated sheet provides high efficiency of filtration and screw is equipped with a brush on it’s edges to ensure cleaning of screen media in filtration zone. The trash retaining screen is made of stainless steel in the form of perforated sheet / wedge wire screen and has larger area for filtration due to inclination in effluent channel. Waste retained on the filtering screen are removed by axially rotating screw conveyer up to waste bin.

This screen can be installed in a Manhole prior to pumps, the size depending on the inflow rate and depth. The sturdy, stable basket screen retains the floating debris at the sewer outlet. The screen bottom plate is perforated to allow static dewatering of the retained material. When a certain amount of material has accumulated, the screen basket is lifted upwards by an electric hoist. The vertical basket movement is supported by a stable carrier and guide rails. These rails are curved in the upper section to ensure a partly automatic discharge into a suitable container. While the screenings are transported upwards in the basket, material which could impair the function of downstream pumps is removed by a fall screen supported on guide rollers. Control of the screen can be either manual or electrical.